The ecological footprint of our human actions, be it the creation of products or the use of them, can be calculated through Life Cycle Assessment (LCA). LCA is a systematic analysis of the environmental impacts of products, processes, or services throughout their entire life cycle, “from cradle to grave”. This includes all environmental impacts during production, use and disposal, as well as the associated upstream and downstream processes, such as the production of raw materials, auxiliary materials, and operating materials. The LCA method can be used as a tool for environmental decision-making and is used to develop and improve products.

The sports field/artificial turf industry has embraced this concept for years, moving from “which system has the best performance?” through to “which field/turf system has the lowest environmental impact?” and is therefore the most “sustainable” system.

One of the first complete LCA studies in this area is the 2021 study by the University of Zurich “Life Cycle Assessment of Turf Sports Fields: Natural, Artificial and Hybrid Turf of the City of Zurich Compared” written by Rene Itten, Lukas Glauser and Matthias Stucki (commissioned by the City of Zurich). The ecological scarcity method is used to assess environmental impacts in all life cycle stages. This study concludes that an artificial turf system has a lower environmental impact per hour of use than a natural grass system or a hybrid system. Ultimately, the number of usage hours is very important in order to compare environmental figures on an equal basis.

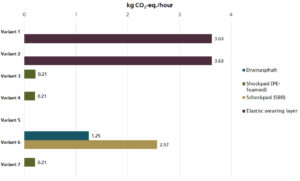

At the end of 2021, the Fraunhofer Institute (UMSICHT) published a multi-client study entitled “Artificial Turf Pitches – System Analysis”. Chapter 13 presents the results of a further Life Cycle Assessment of various artificial turf systems, but limited to CO values. For this purpose, detailed values were given for different types of carpets, but also for various infills and elastic layers. Figure 38 shows a comparison of the manufacturing-related greenhouse gas emissions of different elastic systems in detail.

As part of a national initiative in the construction sector, the Netherlands has now published another Life Cycle Assessment for the National Environment Database Foundation: “LCA Reporting category 3 data National Environmental Database – Chapter 71 – Artificial grass pitches, upper structure (artificial mats and shock pads)”. Clients in the construction industry use these calculations to differentiate between different materials in the design phase of a project. They then compare the MKI (Milieu Kosten Indicator/Environmental Cost Indicator (ECI)) values of different solutions and can then choose the most sustainable material (the product with the lowest MKI value). Alternatively, an award criterion may be applied to the tender for a project whereby the bidder with the lowest ECI value receives the highest notional discount. This study contains all Life Cycle Assessment results, based on the category 3 values provided by the EcoInvent database for different artificial grass carpets including infills, as well as for different types of shock pads. The complex results are summarized in a single value, the ECI value or Environmental Cost Indicator, which is an indicator expressed in euros per m². The indicator is a weighted average and represents the cost of the environmental impact of a product or project.

Conclusion on the ecological footprint of different shock pads

However, the Life Cycle Assessments mentioned above, which differ slightly in their method or in the functional unit chosen and are therefore not directly comparable with each other, all show that a prefabricated shock pad has a much lower ecological footprint than an in-situ e-layer.

Based on the category 3 data of the MKI results, the 25mm elastic layer has more than 24 times the footprint of the 10mm PE foam shock pad. According to this study, it has by far the smallest ecological footprint – even when compared to the prefabricated alternatives in the shock pad sector.

Results on MKI total values for different shock pads:

Considering the MKI value of a 40mm artificial turf with infill at about 1 €/m² from this study, it becomes obvious that the big difference in choosing a sustainable artificial turf system lies in choosing the right shock pad.